Advanced defense systems and reliable equipment are essential to a nation’s daily military operations, including peacekeeping and humanitarian efforts. While these systems and equipment are always under threat of damage, some of these risks can be mitigated with the use of durable, high-quality metal components that support optimum performance and endurance. In this way, a military metal supplier plays a vital role in safeguarding critical defense systems by providing metal parts with the strength, durability, and resistance that are often required by military-grade applications.

Characteristics of Military-Grade Metals

One of the most important aspects of manufacturing metal parts for military applications is proper material selection.

Military-grade metals usually have unique properties that make them suitable for use in military-grade systems and equipment, including superior:

- Strength and toughness

- Durability and resistance to corrosion

- Ability to withstand extreme temperatures and environmental conditions

Some of the most commonly used military-grade metals include steel, aluminum, titanium, stainless steel, and copper. Each possesses unique characteristics that make them ideal for certain applications and less well-suited for others. Military metal suppliers have the knowledge required to select the material that will work best for specific critical applications.

Applications of Military-Grade Metals in Defense Systems

Steel

Known for its superior durability, versatility, and excellent strength-to-weight ratio, steel is ideal for applications that require first-class structural integrity and protection against ballistic threats. Steel is often used in armored vehicles, tanks, submarines, aircraft carriers, and various weapons systems.

Aluminum

Aluminum is best known for its lightweight, corrosion resistance, high conductivity, and malleability. With low density and sufficient strength, aluminum is commonly used in military aircraft, missile components, lightweight armored vehicles, and military-grade body armor. It’s the ideal material for reducing weight, increasing fuel efficiency, and improving mobility.

Titanium

Lightweight and exceptionally strong, titanium has excellent corrosion, heat, and impact resistance properties. Because of this, it is a popular material choice for military aircraft, missiles, and naval vessels. It is also used in armor plating, helicopter rotor systems, and various other critical components such as landing gears and engine parts that need to maintain a high level of performance under stringent conditions.

Stainless Steel

An alloy of steel and chromium, stainless steel combines the best of both for excellent corrosion resistance, durability, as well as resistance to heat and chemical damage. It is often used in applications that require higher levels of resistance, such as firearms, ammunition, naval equipment, jet engine parts, and nuclear submarines due to its ability to withstand harsh conditions.

Copper

Copper is a highly conductive material with excellent thermal, antimicrobial, and ductility properties. As a result, it is the gold standard for more sensitive applications, such as those found in military-grade electronics, electrical wiring, connectors, and communications systems. Alloys of copper can also be found in ammunition casings and high-performance bearings.

The Role of the Military Metal Supplier

Leveraging the full benefits of high-performance metal parts requires the input of an experienced military metal supplier. Military metal suppliers often work closely with defense contractors to develop and supply metal parts that meet stringent specifications and ensure optimal performance and safety. With their deep levels of expertise in material science, metallurgy, and engineering, the military metal supplier is an essential partner in the military and defense world.

By working together throughout the manufacturing process (including design and prototyping), military metal suppliers and defense contractors can push the boundaries of innovation and develop cutting-edge solutions that meet the constantly evolving demands of the military.

Advancements in Military-Grade Metal Fabrication Techniques

The right military metal supplier will deliver more than material selection and part design input; with their expertise in the field, they will also be able to utilize the latest in advanced technology and manufacturing methods to produce parts that meet and exceed expectations.

For instance, additive manufacturing opens the door for increasingly complex designs and the creation of intricate components. With capabilities that allow for customization in parts with complex geometries, military metal suppliers implement additive manufacturing to find new solutions for familiar problems, potentially streamlining the manufacturing process and improving the overall quality of the end-use product by several degrees of magnitude.

In CNC machining and milling, advancements provide military metal suppliers with nearly endless opportunities to innovate and problem-solve. Both processes utilize computer-controlled machines to shape and refine precision metal parts. This ensures the highest levels of accuracy, repeatability, and consistency and is ideal for creating critical components that must meet tight tolerances.

And finally, metal stamping and forming are more traditional methods, but their benefits cannot be overstated. Metal stamping and forming are cost-effective manufacturing methods that allow for the mass production of metal parts that retain the strength and durability that military applications demand.

Secure Your Military Metal Parts with Advantage Metal Products

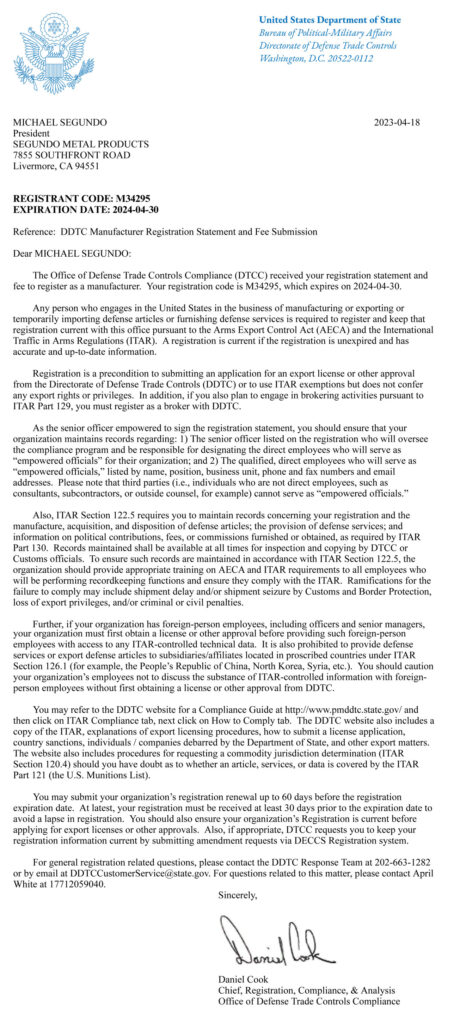

At Advantage Metal Products, we are an ITAR and AS9100D-certified metal manufacturer and fabricator located in Livermore, CA. For more than 30 years, we’ve been providing state-of-the-art metal products and components for a variety of industries, including military and defense.

Our facilities are equipped with the latest in cutting-edge manufacturing technology, enabling us to provide our customers with innovative solutions in custom fabrication, machining, and value-added services.

Are you looking for an experienced metal manufacturing partner for your military-grade metal parts? Connect with our team of experts today to get started.