High quality metal parts are essential to the performance of machinery, equipment, and other critical applications in a wide range of industries. But what exactly factors into high quality metal components? Part design and material choice are two of the topics frequently brought up when quality is a major concern. But one of the most important measures manufacturers can take to ensure quality is to implement robust quality control measures. When implemented correctly, quality control helps ensure the production of parts that consistently meet strict quality standards throughout the manufacturing process.

The Significance of Quality Control in Metal Manufacturing

First, it’s helpful to know what quality control refers to. In metal fabrication, quality control is the systematic processes and techniques that manufacturers employ to ensure metal components meet customer requirements. Through measures such as process controls, inspection and testing, defect identification and correction, and others, manufacturers can optimize their processes to minimize defects and material waste.

Because quality control is such an involved process, it requires a great deal of industry expertise to be fully effective. There are a number of procedures that must be used and challenges that must be faced in order to maximize the production of quality metal parts.

Key Elements of Quality Control for High-Quality Metal Parts

Process Monitoring

Process monitoring is the practice of monitoring and controlling various processes throughout every step of manufacturing. Widely used in cutting, welding, machining and assembly, process monitoring is essential to detect and rectify any process deviations that could lead to part defects.

At its base level, process monitoring should include:

- Data Collection—This can include parameters such as temperature, pressure, speed, time, and other variables that impact product quality.

- Real-Time Monitoring—The real-time collection and analysis of data allows manufacturers to immediately correct deviations and take quick corrective action.

- Setpoint and Tolerance Limits—Monitored parameters are associated with a setpoint (target value) and tolerance limits (acceptable ranges). Deviations outside of this trigger alarms or corrective procedures.

- Sensor Technology—Various sensors and instrumentation measure and monitor process variables, such as thermocouples for temperature, pressure transducers for pressure, and laser sensors for dimensional accuracy.

- Control Charts—Control charts provide graphical representation of process data over time, making it easier to identify trends and patterns for process optimization.

- Feedback Control Systems—Feedback control systems can automatically adjust process parameters in response to detected deviations.

Inspection and Testing

Inspection and testing are fundamental to producing quality metal parts. These two processes involve the examination of materials, components, and products to assess for compliance with standards and quality criteria.

On its own, inspection involves a physical or visual examination to identify defects, deviations, or non-conformities. Often, inspection involves visual inspection, dimensional inspection, functional inspection, attribute inspection, and sample inspection.

Testing, on the other hand, involves subjecting materials, components, or finished products to assess their physical, chemical, mechanical, or electrical properties. Some types of testing include material testing, mechanical testing, non-destructive testing, chemical testing, electrical testing, environmental testing, and functional testing.

Both inspection and testing are essential to compliance and part reliability.

Quality Assurance and Documentation

Quality assurance, or QA, emphasizes the proactive prevention of defects before they happen. The goal of QA is to establish and maintain processes that consistently produce high-quality metal parts. In order to achieve this, quality management systems (QMS), process standardization, risk assessment, supplier quality management, and training and skill development are highly prioritized.

Documentation is a separate but closely related process that involves creating, organizing, and maintaining records related to all aspects of manufacturing. It often includes quality manuals, procedures and work instructions, specifications and drawings, and audit reports. Taken together, QA and documentation help manufacturers maintain regulatory compliance and take a continuous improvement approach to manufacturing.

Meeting the Challenges of Quality Control

Even at the most fundamental level, implementation of strong quality control measures is not without its challenges. When choosing a metal manufacturing partner, it’s essential to find someone with the right approach.

For instance, there are several challenges related to the manufacturing process directly, including variability in materials, welding challenges, dimensional accuracy, and resource and skill constraints. Other challenges are not entirely within the manufacturer’s control but must be accounted for nevertheless. These include regulatory compliance, customer expectations, and the global supply chain.

Addressing these challenges requires a combination of technology, skilled personnel, quality management systems, and a commitment to ongoing improvement. Look for manufacturers that invest in the right training, equipment, and quality control processes.

Experience Quality with Advantage Metal Products

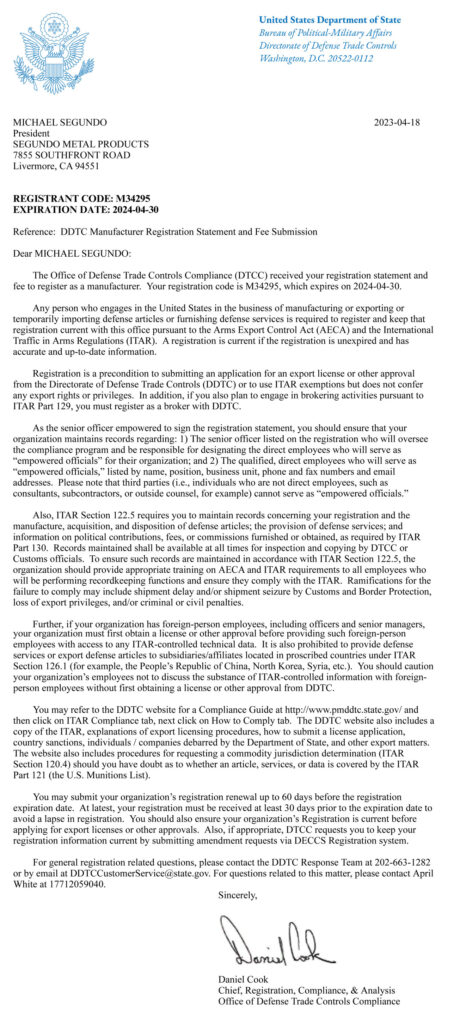

At Advantage Metal Products, we’ve made it our priority to provide high quality metal parts for more than 30 years. Our customers come from a wide variety of industries, including aerospace, medical, and homeland security. Between our team of highly-trained professionals and our U.S.-based facilities equipped with the latest in manufacturing technology, we deliver innovative metal manufacturing solutions that meet our customers’ highest expectations.

Are you looking for quality metal parts that will support your needs? Connect with our team today to get started.