Choosing between sheet metal vs machined components is one of the earliest decisions engineers make and one that heavily impacts cost, lead time, and performance. Both processes can deliver high-quality parts, but each excels in different scenarios.

Here’s a simple guide to help determine which manufacturing path best fits your design.

1. Geometry: How Complex Is the Shape?

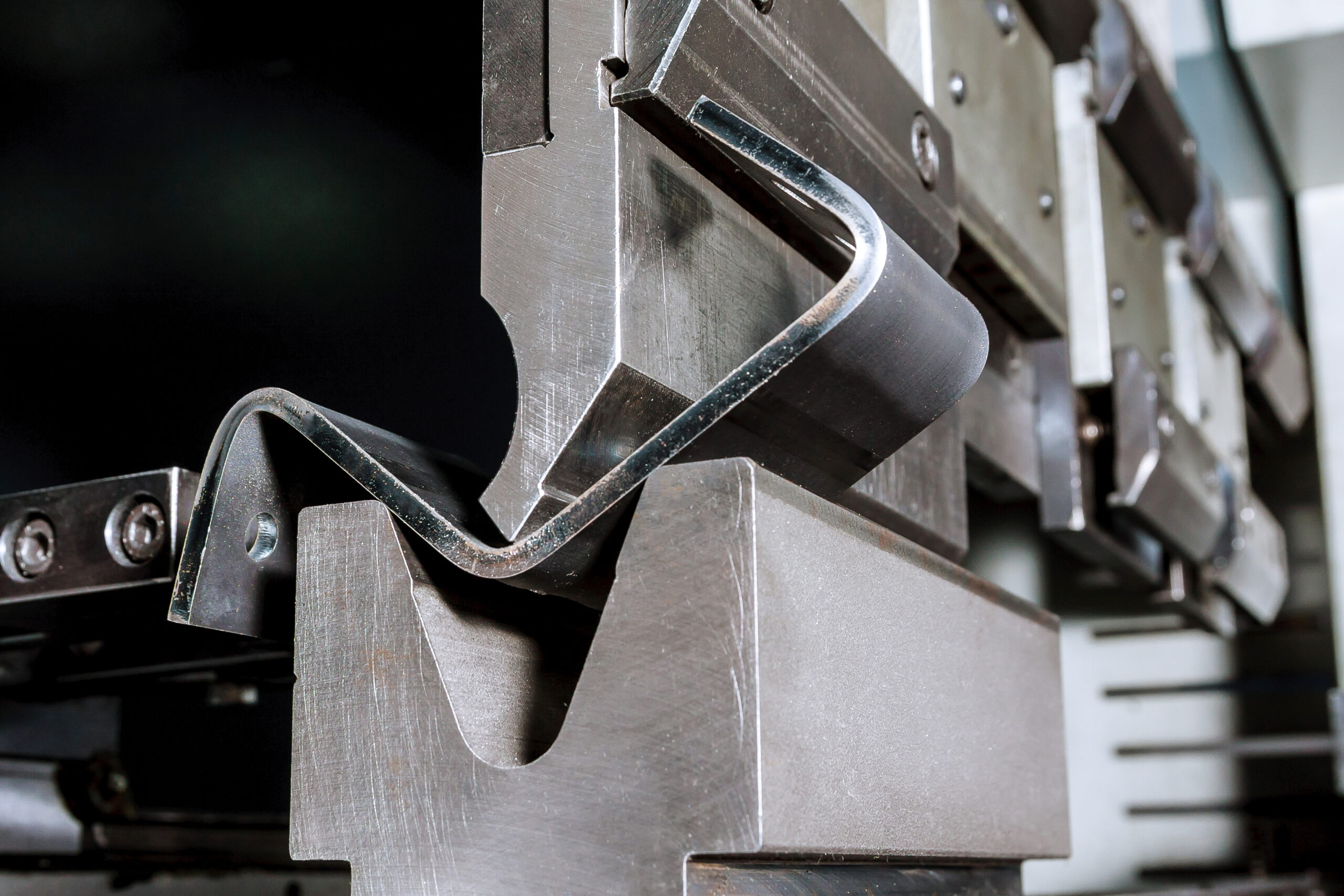

Choose Sheet Metal when:

- The design is defined by bends, flanges, or flat patterns

- You need lightweight brackets, enclosures, or chassis

- Most features can be formed instead of cut

Choose Machining when:

- The part requires pockets, contours, or deep cavities

- Precision surfaces or 3D geometry are important

- Internal features or multi-plane designs are involved

If the geometry can be created from a flat pattern, sheet metal is often the best fit. If not, machining usually takes the lead.

2. Cost: What’s the Most Efficient Path?

Sheet Metal

- Less material waste

- Faster production

- Lower cost for mid-to-high volumes

Machining

- Higher cost due to material removal and cycle time

- Best value when precision or complexity requires it

For many designs, the cost difference between sheet metal vs machined components becomes clear once strength, geometry, and tolerances are considered.

3. Strength & Material Requirements

Sheet Metal

- Relies on bends and formed features for rigidity

- Works well with aluminum, stainless, and cold-rolled steel

- Ideal for thinner materials and lightweight structures

Machining

- Supports thicker, high-strength components

- Allows variable wall thickness and rigid geometries

- Handles a wide range of materials, including tough alloys

If the part must withstand significant load or needs thick sections, machining may be the better choice.

4. Tolerances: How Precise Must It Be?

Sheet Metal

- Good for standard commercial tolerances

- Bend variability must be accounted for

Machining

- Best for tight tolerances, mating surfaces, and critical fits

When precision drives product performance, a machined component typically offers the accuracy required.

5. Scalability: How Will the Part Be Produced?

Sheet Metal

- Excellent for prototypes and large-volume production

- Minimal tooling and fast iteration

Machining

- Great for prototypes and low-to-medium volumes

- More costly at large volumes unless automated

Prototype needs, production goals, and cost targets all influence the sheet metal vs machining decision.

6. When a Hybrid Approach Makes Sense

Many assemblies perform best when sheet metal and machined components are combined, such as:

- Enclosures with machined mounting features

- Sheet metal housings with precise machined interfaces

- Lightweight designs requiring both rigidity and accuracy

This is one of AMP’s biggest strengths both capabilities are available under one roof, reducing lead time, cost, and vendor complexity.

Conclusion

Choosing between sheet metal vs machined components depends on:

- Geometry

- Strength

- Tolerances

- Budget

- Volume

- Scalability

Both processes bring unique benefits, and many parts benefit from a hybrid approach. At AMP, we help customers evaluate the best manufacturing method from early prototypes through full-scale production.

Follow us on LinkedIn HERE.

Contact us HERE.