Blog

From Sheet Metal Parts to High-Tech Components: How to Streamline Manufacturing Partnerships

When it comes to delivering quality sheet metal parts and high-tech components, effective manufacturing partnerships are key. Manufacturers can reduce lead times, streamline production, and enhance the quality of your sheet metal components. Partnering with a reputable manufacturer is especially important in vital industries, like aerospace or defense, where proper product performance is mission-critical. Working […]

Precision, Compliance, and Innovation: What Makes a Military Machine Shop Stand Out

Military equipment must function flawlessly under the most extreme pressures imaginable — from the scorching heat of desert warfare to the corrosive conditions of maritime operations. Behind every successful mission stands an array of precision-manufactured components, each one critical to operational success. The right military machine shop shoulders this responsibility daily, producing parts that must […]

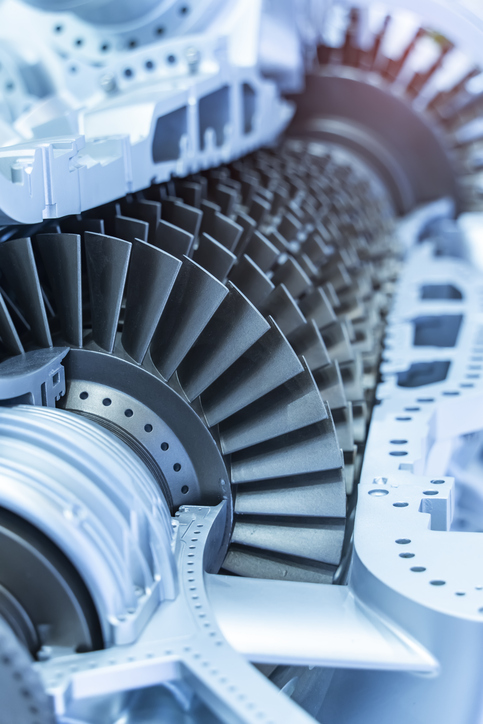

The Secrets to Success in Aerospace Machine Shops: Meeting Demands for High-Tolerance Components

When a commercial aircraft takes flight, it relies on thousands of precision-engineered components working in perfect harmony. Behind each of these critical parts stands aerospace machine shops, where precision manufacturing makes the difference between optimal performance and potential failure. From critical engine components to sophisticated landing gear systems and essential structural parts throughout, the reliability […]

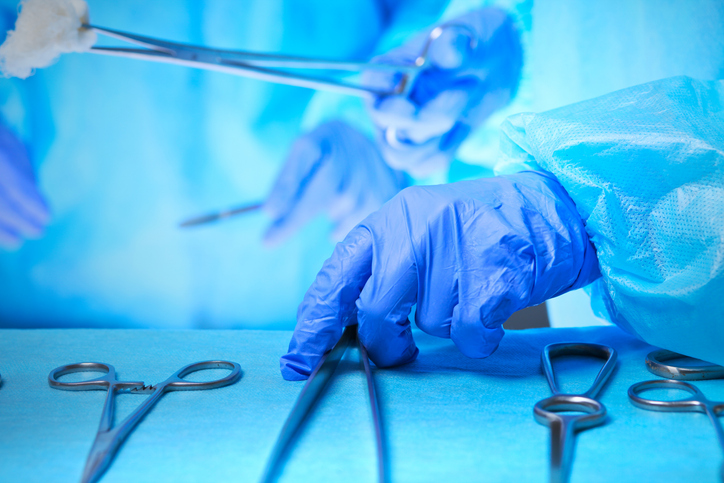

Medical Device Parts Manufacturing: Key Considerations for Biocompatibility and Sterilization

Of all the industries that rely on metal components, almost none are as heavily regulated as the medical device sector. Precision and reliability aren’t just about performance — they’re integral to ensuring patient safety and care. For this reason, manufacturers of medical device parts must be able to meet strict requirements to ensure that every […]

Defense CNC Machining: How Advanced Manufacturing is Powering Next-Gen Military Technology

Defense systems are growing increasingly complex. From AI tools for air defense and drone swarms, to 6th-gen fighters and network kits for armored vehicles, the need for high-quality manufactured components has never been higher. But these systems often require parts with tight tolerances and intricate designs that can be reliably manufactured in high volumes. That’s […]

5 Challenges in Defense Metal Fabrication (And How Advanced Machining Solves Them)

In the defense industry, specialized metal components are necessary for high-stakes applications like military vehicles, armor, and weaponry. In such a demanding field, every part is critical — they must be able to withstand harsh conditions and meet exacting standards for durability, precision, and safety, all while living up to the highest performance standards. This […]

Precision Meets Innovation: The Role of CNC Machining in Medical Component Manufacturing

In the medical industry, precision in manufacturing is essential. Metal components that are used in medical devices, in particular, must meet exacting standards to ensure they perform safely and reliability, whether they’re part of life-saving equipment or tools used in daily procedures. For this purpose, fewer manufacturing methods rise to the occasion like CNC machining. […]

The Benefits of High Tech Metals in Defense Components

As military and defense technologies have evolved, high tech metals have become indispensable to a number of critical applications. Metal parts in this sector must be able to withstand extreme conditions and deliver exceptional performance at the same time. Luckily, advancements in metallurgy, including the development of lightweight alloys, high-strength steels, and corrosion-resistant materials, have […]

The Impact of Precision Machined Metal Parts on Aerospace Technologies and Applications

In modern manufacturing, precision machined metal parts are critical, especially for industries that have exacting standards and complex design requirements. Nowhere is this more evident than in aerospace, where safety, performance, and reliability are paramount. For these applications, precision machining allows for the creation of intricate metal parts with micron-level tolerances which help ensure that […]